Why Should Human Still Drive Forklifts?

A Shanghai company Mooe Robots is making forklifts fully autonomous

Self-driving forklift manufacturer Mooe Robots (木蚁机器人)has recently received nearly 100 million yuan (US$15M) in their B+ financing round. This round of financing was invested by Chentao Capital and Lanchi Ventures. The funds will be mainly deployed to increase investment in the research and development of indoor and outdoor driverless vehicle product lineup, promote the implementation of large-scale multi-scenario projects, build the intelligent system, and the development of markets such as wholesale fresh produce markets.

The Mooe Robots Company was established in 2016 in Shanghai China. Since 2019, it has entered the warehousing and logistics industry with unmanned forklifts, and has focused on handling scenarios such as large-volume, high-density, and high-frequency logistics hub centers. At present, the products that have been launched include Mooe-F1 Pro and Mooe-F2 X.

In traditional logistics hub centers, forklifts are controlled mainly by human drivers to deliver the highly mechanical repetitive task in the high density and complex environments. With the rising labor cost, difficulty in driver recruitment and the low degree of intelligence of traditional forklifts, the difficulty of forklift management training has become a significant constraint in the logistics industry.

Automated Distribution Centers

Mooe Robots are designed to solve exactly the above problems at the logistics hubs. Their advantages are below:

Stability and cost control at the hardware level. At present, the Mooe Robots have achieved a stable operation of over 1.2 million kilometers in the scenario of a high-density, high-frequency logistics distribution center. In addition, by optimizing sensors, control systems, and interface boards, costs are controlled and operational efficiency is improved.

The perception and prediction ability at the software level. Especially in the high-density operation in the outdoor environment, high-precision positioning and perception are required. At the same time, in the face of complex scenarios such as congestion and obstacles, how to re-plan the route to make the diversion faster and more efficient at high speed has put forward requirements on the prediction ability of the system.

Founder and CEO Qian Motian explained that the core advantage of the Mooe Robots lies in the sophisticated understanding of the scenes in real time. Mooe Robots focus on high-volume, high-density, high-frequency “express delivery” scenarios. “At present, we have served companies including Debon, Yunda, Anneng, Leaping, Yimidida and up to 70% of the leading companies in the field of logistics. We recently achieved a milestone of having 100 unmanned forklifts working simultaneously in a single warehouse.” explained Qian in a recent interview.

Group Scheduling System

The unique autonomous driving technology architecture of Mooe Robots allows the machines to make the frog leap from low-speed single machine intelligence to high-speed group machine intelligence. The fully unmanned forklifts can be deployed at indoor warehouses as well as outdoor parks, wholesales markets and other high traffic scenarios.

Specifically, in terms of single machine intelligence, the Mooe Robots can achieve a high-speed transportation rate of 2.6 m/s, which is more suitable for a variety of transportation scenarios compared to the industry's average travel speed of 1.5 m/s. At the same time, through 3D SLAM, the indoor and outdoor navigation module is realized to improve the perception of the unmanned forklift to the environment enabling long-distance identification of obstacles and automatic avoidance manoeuvres.

Swarm intelligence is at the core of the real breakthrough of Mooe Robots, based on a robust scheduling system on a distributed service architecture, which enables simultaneous scheduling of up to 100 machines in operation in a single scenario. At the same time, this system can also realize PDA human-computer interaction. In addition, it also supports the data management of the entire warehouse location for the landing scene, including WMS management, pallet information, cargo data management, and even labor salary management.

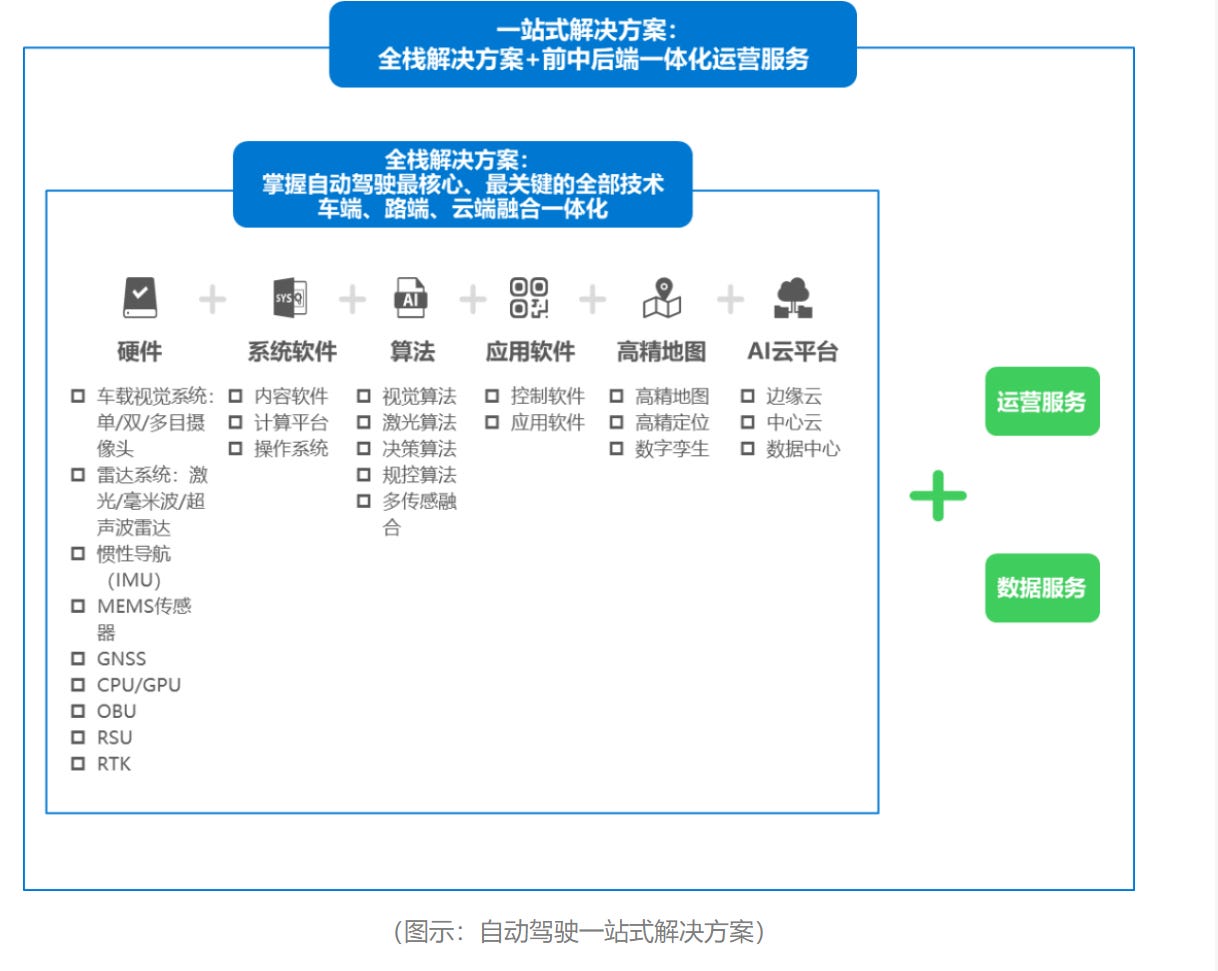

vehicle-road coordination (V2X) is a key concept incorporated in the development of the full stack autonomous driving technology. Much superior to the traditional two-dimensional code navigation and scheduling used by traditional forklifts, the Mooe Robots adopt the scheduling design based on accurate 3D models generated in real time of the road conditions.

One-stop Autonomous Driving

As for future development, Qian Motian said, "Mooe Robots uses the logistics hub as its base to provide full-stack handling solutions through 'group autonomous driving' technology. It has focused on commercial deployment of high-density handling scenarios in day and night operations around the clock for more than two years now. In the future, Mooe Robots will further improve the 'group intelligent sorting system', increase business increments by more than 3 times, and expand outdoor group automatic handling scenarios to larger geographical space with even higher traffic complexity"

In fact, from indoor work to outdoor, a core difficulty that needs to be overcome is the perception ability. "The road conditions and environments in outdoor scenes are more complex, but at the same time, the speed requirements are also higher, so it is necessary to achieve a wider range and higher accuracy of perception."

In the outdoor scene of landing, the F2-X unmanned vehicle series is suitable for complex environments such as cold chain logistics parks, outdoor logistics parks, agricultural and sideline products bazaars, wholesale markets, and cargo forwarding services. For scenarios such as fairs and trade parks, Mooe Robots will also build a platform-based operating system in software to realize the scheduling of people, vehicles and goods. "At the moment, the scale of the handling market in outdoor scenarios is as high as trillions, and there are still a lot of manpower vacancies, so the space is vast."

The core technical team of the company came from the United States United Technology Research Center, Alibaba Dharma Academy, JD.com, Huawei, etc., and has accumulated rich experience in the fields of unmanned driving, artificial intelligence and intelligent logistics. Among them, the founder and CEO Qian Motian has 13 years of experience in the mobile robot industry, and is a senior robot system architecture engineer.

As the investor of this new financing round, He Xiongsong, Executive General Manager at Chentao Capital, said: "The Mooe Robot have established a leading position in the field of logistics connections with their fully unmanned forklifts. From indoor to outdoor, it is the first company to solve the complex outdoor park transfer scene. This is a 100 billion yuan market by itself. We are firmly optimistic about Mooe Robots’s strong brand positioning in the market on top of a truly outstanding team.”

Cao Wei, partner of Lanchi Ventures, said: "Forklifts are ubiquitous products in the manufacturing and logistics industries with a remarkable scale globally. The Mooe Robots team has a solid track record of executing their solution for difficult and complex scenarios such as large-scale distribution centers, warehouses and outdoor logistics parks. The company is well recognized by a large number of leading customers. The current overall market penetration rate of fully autonomous forklifts is still very low, presenting a massive market for Mooe Robots.”

-MrFlywheel | China Tech Briefing (only the local stuff)